16 inch Two roll mill

Model No.︰XK-400

Brand Name︰HUAHAN

Country of Origin︰China

Unit Price︰CNY ¥ 14000 / pc

Minimum Order︰1 pc

Product Description

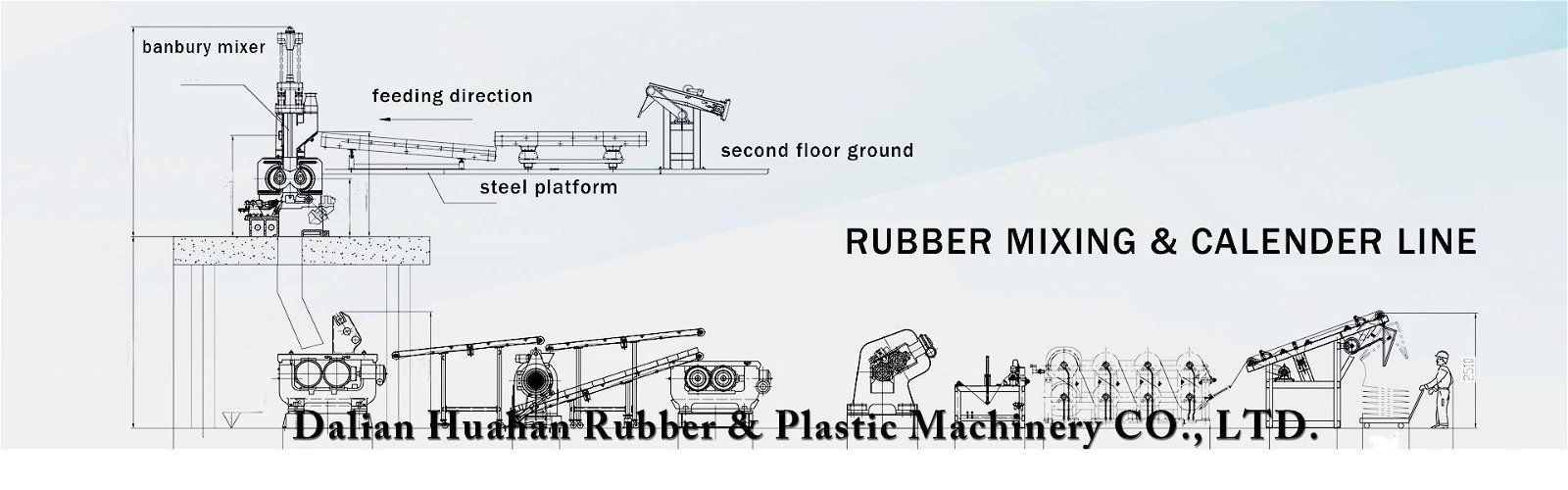

1.The machine is used for raw rubber plasticating and mixing, warm-up or sheeting of rubber. It is a general equipment in rubber industry.

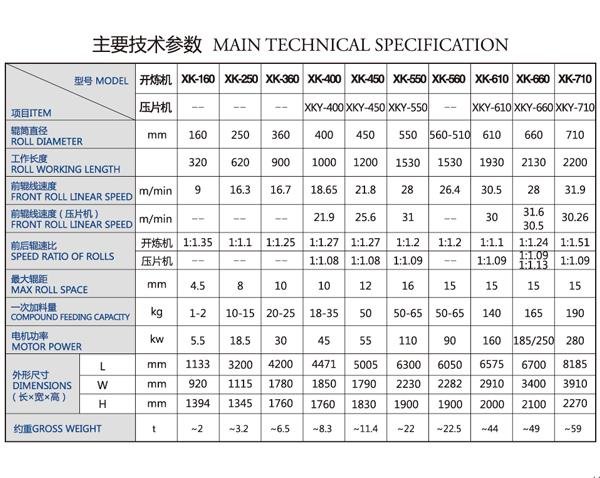

2.Technical specification

2.1. Transmission direction user specified

2.2. Front roller form: hollow roller

back roller form: hollow roller

2.3. roller size of Φ400 × 1000mm

2.4. Front roller line speed 19.3m/min

2.5. Roller speed ratio 1:1.27

2.6. Main motor rated power 45kW

Rated speed 980r/min

2.7.Nip adjusting device adjustable, by hand

2.8 Batch rubber capacity 50kg (proportion 1.15)

2.9 Size ~5000×1900×1830mm

3. Structure description

3.1 Simple design framework and easy to operate.Start running as soon as connecting wire and pipeline

3.2 Rollers:they are made of chilled alloy cast, the surface hardness is HS70±2.Chilled thickness 8-15mm.

3.3The roller bearing is rolling bearing,Can save power 5-8%, bearing end use grease lubricating.Bearing ends seal use no skeleton seal,

3.4Roller bearing lubrication: grease lubrication, equipped with manual or motor driving grease pump;

3.5The speed redducer is the hard-toothed reducer of Class 6 precision,which has long service life and low noise.

3.6 Bearing seat: after annealing using cast steel, processed, and lubricating oil hole;

3.7. Nip adjusting device: adjustable, by motor ,composed of hand wheel, worm, worm bar, dial;

3.8. Frame and cover: frame material is cast iron, cast steel after annealing treatment for cover material;

3.9. Base plate: base adopts an integral type welded structure, annealing treatment;

3.10 Stock guider: It has different types, manully, hyraulicly.

3.11. Driving system: the main motor through the shaft coupling, gear coupling, gear and machine speed roller relative operation;

3.12.Perfect emergency stop device can ensure the safety of person and of equipment.

3.13. Emergency stop and braking device: the braking, e is emergency stop button on the frame, when there is an emergency, roller forward rotation is not more than 1/6 circle, and has the reverse function.

Payment Terms︰ TT/LC/

Product Image